Premium Packaging Machine Repair Service to Optimize Manufacturing Efficiency

Premium Packaging Machine Repair Service to Optimize Manufacturing Efficiency

Blog Article

Understanding the Secret Elements and Repair Methods for Packaging Equipment Maintenance

Reliable maintenance of product packaging devices rests on a complete understanding of their essential parts, including the frame, drive system, and securing mechanisms. Acknowledging typical maintenance problems, paired with the execution of preventative methods and fixing strategies, can considerably enhance device dependability. The option of repair service techniques, including the usage of OEM components and the importance of licensed technicians, plays a vital role in lessening downtime. To absolutely grasp the complexities of these systems and their maintenance, one have to think about the wider effects of overlooking these essential methods.

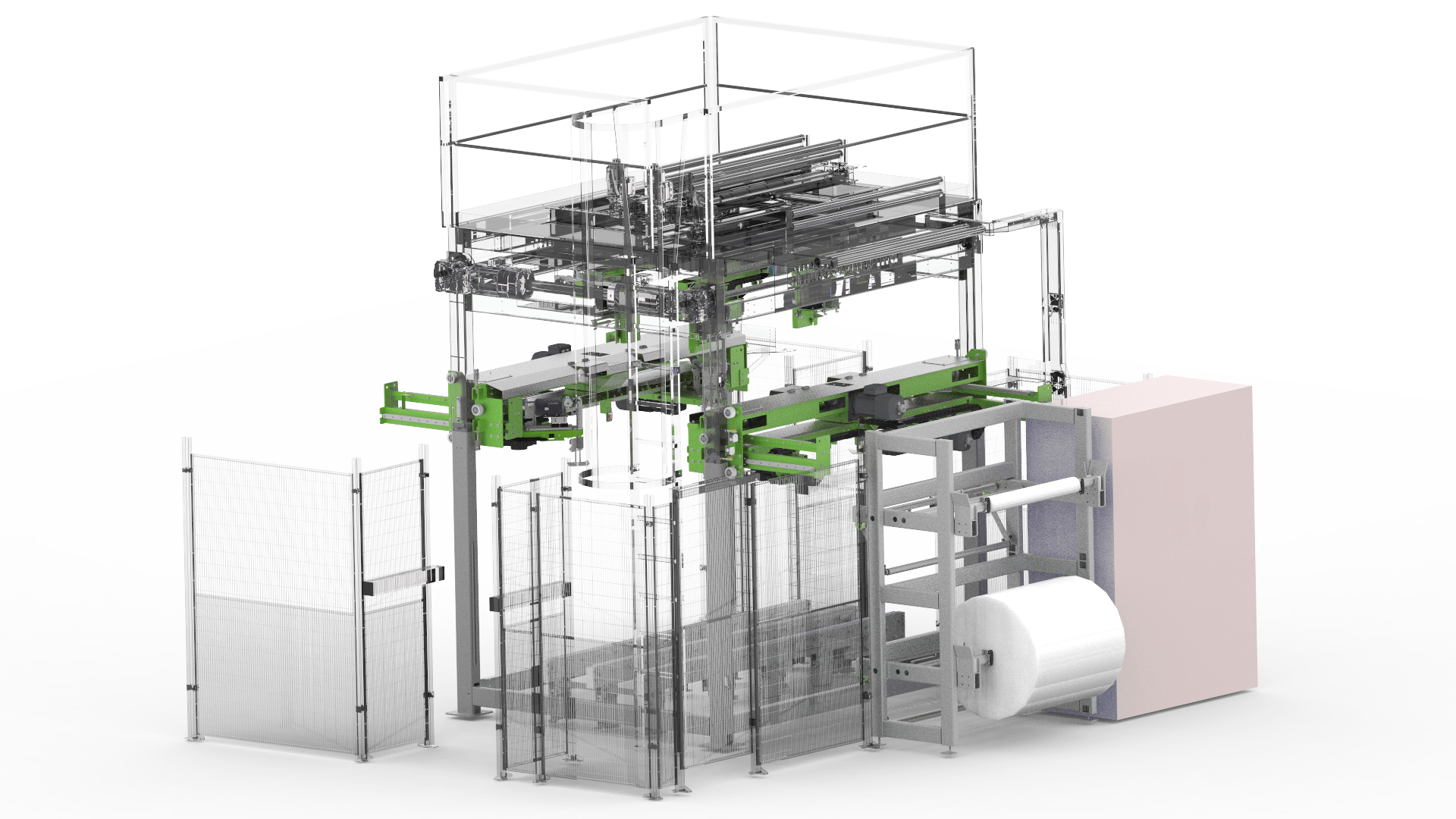

Secret Components of Packaging Machines

Packaging machines are composed of numerous crucial parts that interact to make sure reliable and effective product packaging procedures. At the core of these makers is the framework, which offers architectural honesty and houses the numerous operating components. The drive system, commonly a combination of motors and equipments, helps with the motion of parts, allowing accurate procedure throughout the product packaging cycle.

One more important element is the conveyor system, which carries items through different phases of the packaging procedure. This is often matched by sensing units and controls that monitor the setting and rate of products, ensuring synchronization and decreasing errors. The filling up system is critical for accurately dispensing the best amount of product into bundles, whether in liquid, powder, or solid type.

Securing mechanisms, consisting of heat sealers or sticky applicators, play a crucial duty in safeguarding bundles, avoiding contamination and extending service life. Furthermore, classifying systems are important for offering necessary product information, making sure compliance with laws. The control panel, geared up with straightforward user interfaces, allows drivers to manage equipment features, screen performance, and make adjustments as required, making certain optimum performance and effectiveness in packaging operations.

Usual Maintenance Issues

Efficient procedure of product packaging makers depends greatly on routine upkeep to avoid usual concerns that can disrupt production. Amongst these issues, mechanical damage prevails, particularly in components like electric motors, conveyors, and seals, which can bring about unforeseen downtimes. Furthermore, imbalance of parts can result in inefficient procedure, causing items to be inaccurately packaged or damaged throughout the process.

Another usual upkeep issue involves the accumulation of dirt and debris, which can hinder the maker's sensing units and moving components. packaging machine repair service. This not just affects performance however can additionally position safety and security risks. Furthermore, lubrication failings can cause enhanced rubbing, leading to overheating and eventual element failing.

Electrical problems, usually originating from loosened connections or worn-out circuitry, can disrupt equipment functions, bring about substantial manufacturing hold-ups. Software application problems due to inappropriate setups or outdated programs can impede the maker's procedure, demanding prompt treatment. Resolving these usual upkeep issues proactively is vital for guaranteeing optimal efficiency and long life of product packaging equipment.

Preventative Maintenance Methods

Applying preventative maintenance strategies is crucial for sustaining the effectiveness and dependability of product packaging makers. These approaches incorporate an organized strategy to upkeep, concentrating on the routine assessment and maintenance of devices to preempt potential failures. By sticking to a scheduled maintenance program, operators can identify wear and tear on elements before they cause substantial breakdowns.

Crucial element of a preventative maintenance approach include routine assessments, lubrication, cleaning, and part replacements based upon maker suggestions. Utilizing lists can streamline this procedure, making certain that no essential jobs are neglected. Additionally, preserving exact records of maintenance activities help in tracking the device's performance over time, helping with notified decision-making regarding future upkeep demands.

Educating team on the importance of preventative maintenance enhances conformity and cultivates a society of aggressive treatment. Implementing an anticipating maintenance component, utilizing data analytics and sensor innovation, can additionally enhance equipment efficiency by forecasting failings before they occur.

Troubleshooting Methods

When encountered with malfunctions or ineffectiveness in product packaging machines, utilizing systematic troubleshooting methods is necessary go now for recognizing and settling concerns quickly. The initial step in reliable troubleshooting is to develop a clear understanding of the device's functional criteria and efficiency metrics. This entails evaluating the machine's specifications, along with any type of error codes or alerts shown.

Next, drivers ought to conduct an aesthetic evaluation, checking for evident signs of misalignment, damage, or wear. This frequently includes checking out sensing units, gears, and belts to identify potential sources of breakdown. Collecting operational data, such as manufacturing rates and downtime logs, can additionally offer Learn More Here understandings into persisting concerns.

Once potential troubles are determined, utilizing a logical technique to isolate the source is critical. This might require testing private elements or systems in a controlled way. Participating in conversations with drivers who engage with the machinery on a regular basis can generate important comments about uncommon habits or patterns.

Repair and Replacement Ideal Practices

A detailed understanding of repair service and substitute ideal methods is vital for keeping the long life and effectiveness of packaging devices. Routinely evaluating the condition of device parts enables for prompt intervention, protecting against more significant issues that can cause expensive downtimes.

When repair work are essential, it is necessary to use OEM (Original Devices Manufacturer) components to make sure compatibility and performance. This not just protects the honesty of the device yet likewise supports warranty arrangements. Furthermore, it is a good idea to preserve an inventory of critical extra parts to facilitate quick replacements and decrease operational disruptions.

For intricate fixings, engaging certified specialists with specialized training in product packaging machinery is recommended. They possess the know-how to identify problems accurately and perform fixings successfully. Recording all fixing activities and parts substitutes is critical for preserving a detailed maintenance history, which can assist in future troubleshooting.

Last but not least, implementing a positive method, including routine inspections and predictive upkeep methods, boosts the dependability of product packaging devices. By sticking useful reference to these best techniques, businesses can make certain ideal machine efficiency, decrease functional dangers, and expand devices lifespan.

Conclusion

In verdict, an extensive understanding of packaging maker parts and reliable upkeep methods is vital for optimum efficiency. By carrying out these practices, organizations can make certain the long life and performance of packaging equipments, ultimately contributing to improved operational productivity and decreased expenses (packaging machine repair service).

Efficient upkeep of product packaging devices pivots on a detailed understanding of their essential parts, including the frame, drive system, and sealing devices.Effective procedure of packaging makers depends greatly on routine maintenance to prevent usual problems that can disrupt manufacturing.Carrying out preventative upkeep techniques is vital for maintaining the efficiency and dependability of product packaging equipments. Additionally, preserving accurate documents of upkeep activities help in tracking the maker's performance over time, facilitating notified decision-making concerning future upkeep demands.

Report this page